WHAT IS ESD ?

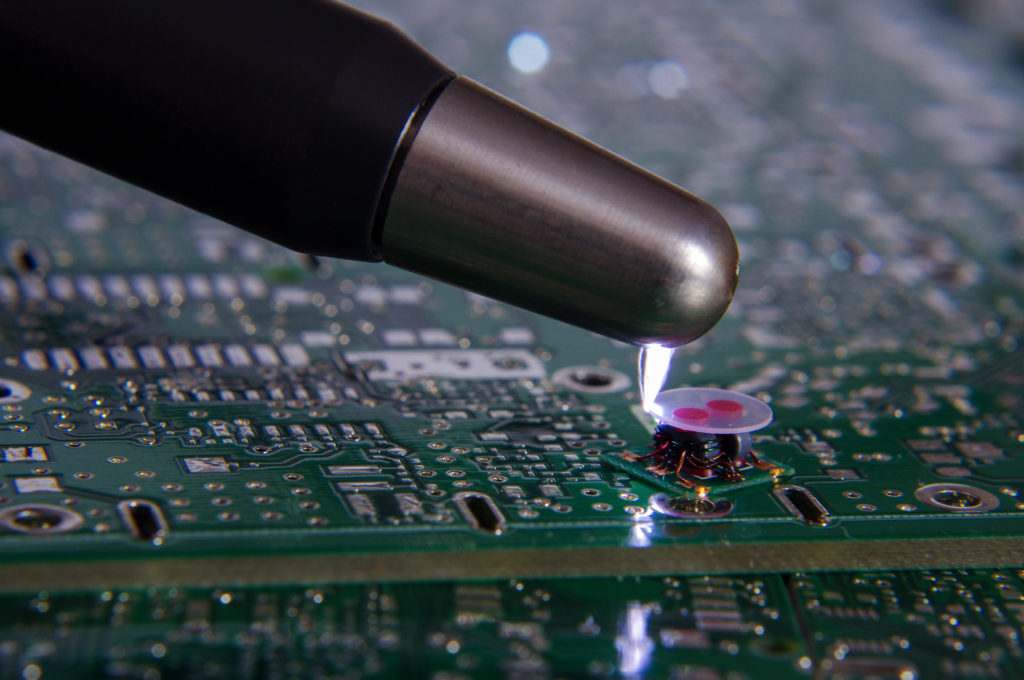

Electrostatic Discharge (ESD) refers to the sudden flow of electricity between two objects with different electrical potentials, typically caused by contact, an electrical short, or dielectric breakdown. This can occur when a person or object accumulates static electricity and then touches an electronic component or surface

Basic Awareness of Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) is the sudden flow of electricity between two objects due to static electricity buildup. It can cause serious damage to sensitive electronic components, so understanding and preventing ESD is crucial in electronics manufacturing and repair.

ESD CONTROL

Electrostatic Discharge (ESD) Control refers to the set of measures and precautions used to prevent electrostatic discharge from damaging sensitive electronic components. ESD can cause immediate failure or latent defects, leading to product malfunctions over time.

Why is ESD Important?

ESD can cause serious damage to sensitive electronic components, leading to:

- Product failure (immediate or latent defects)

- Reduced reliability in electronic devices

- Increased costs due to rework, repairs, or product recalls

ESD in Manufacturing & Industry

To prevent damage, industries handling electronic components (such as semiconductors, PCBs, and circuit boards) implement ESD control measures like:

- ESD-safe workstations (grounded mats, chairs, and tables)

- Personnel grounding (wrist straps, ESD shoes, and clothing)

- Controlled environments (humidity control, ionizers, and flooring)

- ESD-safe packaging (shielding bags, trays, and conductive boxes)

Since PBSS manufactures ESD products, your company likely produces items that help control and prevent electrostatic discharge in industries where static damage is a risk

Stay Static-Free with PBSS

ESD SAFE ICONS

ESD-safe icons are used to indicate electrostatic discharge protection in products, workplaces, and packaging. Here are the most commonly used ESD symbols:

1. ESD Protective Symbol

🔶 Meaning: Identifies ESD-safe items such as tools, equipment, and workstations.

🟡 Appearance: A yellow triangle with a hand reaching toward a line (representing electrostatic sensitivity).

📌 Use: Found on ESD-protected areas (EPAs), anti-static packaging, and ESD-safe materials.

2. ESD Susceptibility Symbol

⚠️ Meaning: Warns that the device or component is sensitive to electrostatic discharge and requires handling precautions.

🟡 Appearance: A yellow triangle with a hand and a diagonal line (slash) crossing it.

📌 Use: Printed on PCBs, semiconductors, and electronic components prone to ESD damage.

3. ESD Protective Area (EPA) Symbol

📍 Meaning: Marks areas where ESD control measures are enforced, such as ESD-protected workstations.

🟡 Appearance: A footprint icon inside a yellow triangle or a sign saying “ESD Protected Area”.

📌 Use: Placed at entry points to ESD-safe zones in manufacturing plants and labs.

Losses Due to Lack of ESD Control

Failing to implement proper Electrostatic Discharge (ESD) control can lead to serious financial, operational, and reputational damage. Here are the key losses that can occur:

1. Product Damage & Failures

⚡ Immediate Failures: Components get damaged instantly, leading to defective products.

⚠️ Latent Failures: Even if a product appears to work, ESD damage weakens it, leading to unexpected failure later.

💰 Increased Returns & Warranty Claims: Faulty products result in customer complaints, refunds, and replacements.

2. Increased Production Costs

🛑 Scrap & Rework: Damaged components must be discarded or reworked, wasting materials and labor.

⏳ Downtime & Delays: ESD-related failures in production cause interruptions and missed deadlines.

🔧 Additional Testing & Repairs: Extra quality control measures are needed to catch ESD-damaged products.

3. Business & Reputation Losses

🚨 Customer Trust Issues: Delivering faulty products damages brand reputation and customer loyalty.

⚖ Compliance Violations: Failure to follow ESD standards (e.g., ANSI/ESD S20.20, IEC 61340-5-1) can result in legal or certification issues.

📉 Loss of Contracts & Business Opportunities: Clients prefer suppliers with strict ESD control measures to ensure quality.

How PBSS Can Help Prevent These Losses

Since PBSS manufactures ESD products, promoting strong ESD control can:

✔ Protect sensitive components from damage.

✔ Reduce production losses and increase efficiency.

✔ Ensure compliance with international standards.

✔ Maintain customer trust and industry reputation.