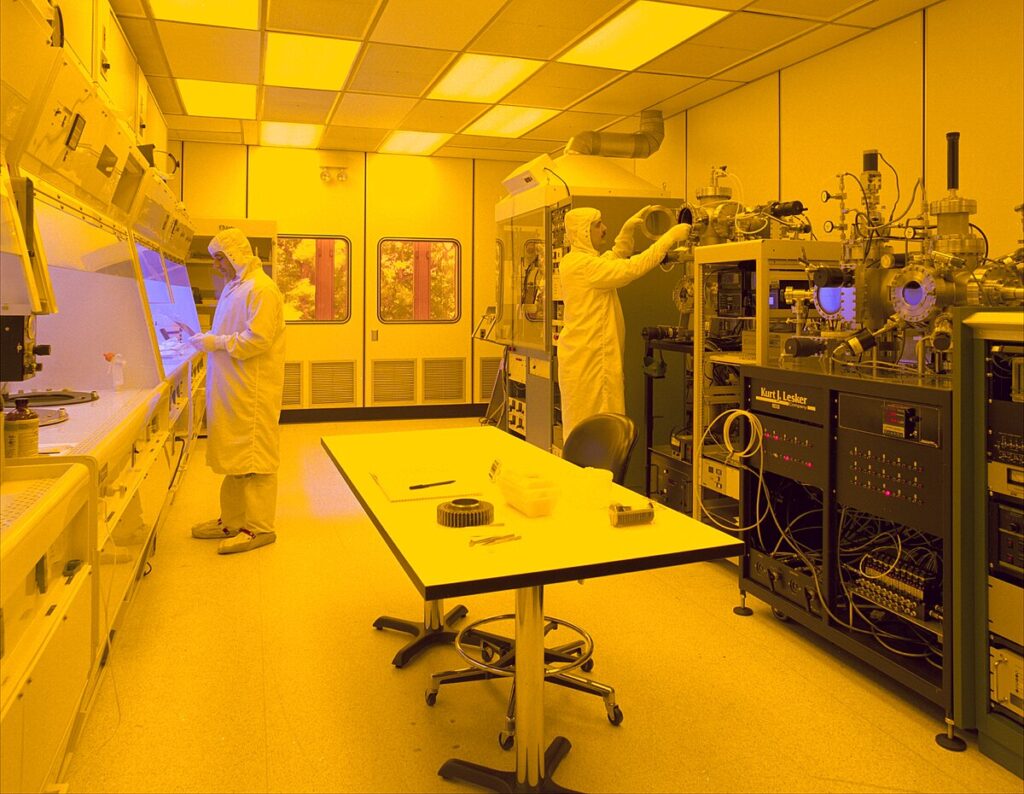

What is Cleanroom?

A cleanroom is a controlled environment that minimizes the presence of airborne particles, contaminants, and pollutants. It is designed to maintain low levels of particulates, such as dust, airborne microbes, and chemical vapors, to ensure the production or research activities within it are not compromised by contamination. Cleanrooms are commonly used in industries like semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace, where precision and cleanliness are critical

Cleanroom technology

Cleanroom technology refers to the design, construction, and maintenance of environments with controlled levels of contamination. These environments are used in industries where even minute particles can adversely affect processes or products. This is crucial in sectors like pharmaceuticals, biotechnology, electronics, aerospace, and semiconductor manufacturing.

Key elements of cleanroom technology include:

Air Filtration: Cleanrooms rely on high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters to remove particles from the air.

Airflow Management: Proper airflow design, including laminar or unidirectional flow, helps ensure particles are swept away from sensitive areas.

Temperature and Humidity Control: Maintaining a constant temperature and humidity is important to reduce the risk of contamination or damage to products.

Personnel Protocols: Strict protocols for personnel entering and working in cleanrooms, such as wearing protective clothing, face masks, gloves, and following specific procedures to minimize particle introduction.

Room Classification: Cleanrooms are classified according to the number and size of particles allowed in the air, with the most common classification system being the ISO 14644-1, ranging from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean).

These measures help create an environment suitable for precise and sensitive tasks like pharmaceutical manufacturing, semiconductor assembly, or medical device production.

Cleanroom control

Cleanroom control* refers to the systems, procedures, and measures used to maintain the desired cleanliness levels and environmental conditions in a cleanroom. This involves controlling factors like air quality, temperature, humidity, and pressure to prevent contamination and ensure that sensitive processes or products are not affected by unwanted particles or microorganisms.

Key components of *cleanroom control* include:

Air Quality Control:

Filtration: Cleanrooms use high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters to remove airborne particles. Regular maintenance and monitoring of these filters are essential to ensure they are functioning effectively.

Air Changes: The air exchange rate (measured in air changes per hour, ACH) is controlled to ensure that enough clean air is circulated to maintain particle-free conditions. The required ACH varies depending on the cleanroom’s classification (e.g., ISO Class 5 or Class 7).

Particle Monitoring: Continuous monitoring systems measure the concentration of particles in the air to ensure they do not exceed acceptable limits. Particle counters are often installed to track particle levels in real-time.

Pressure Control:

Pressure Differential: Cleanrooms often require specific pressure differentials relative to surrounding areas to prevent contamination. For example, the cleanroom may need to maintain positive pressure to ensure that air flows out rather than in, keeping contaminants from entering. Conversely, areas where contamination is a concern (e.g., dirty rooms) may need to maintain negative pressure.

Pressure Sensors and Alarms: Systems continuously monitor pressure and can trigger alarms if pressure differentials fall outside acceptable ranges.

Temperature and Humidity Control:

Temperature Control: Cleanrooms often require precise temperature regulation, particularly in industries like pharmaceuticals or electronics. Typically, temperatures are maintained between 18°C to 24°C (64°F to 75°F), but exact requirements depend on the application.

Humidity Control: Humidity levels are also controlled to prevent static electricity build-up, moisture-related product issues, or microbial growth. Humidity levels in cleanrooms are typically kept between 30% and 60%.

Monitoring Systems: Automated systems are used to track and adjust temperature and humidity in real time. In critical areas, these systems are integrated into a Building Management System (BMS) to provide alerts if conditions deviate from the set parameters.

Airflow Control:

Laminar Flow: Cleanrooms often use laminar airflow (unidirectional airflow) to ensure particles are swept away from sensitive areas and toward exhaust vents. This is particularly important in areas where high precision is required, such as in semiconductor manufacturing or drug production.

Air Handling Units (AHUs): Cleanrooms are equipped with air handling systems that regulate airflow, temperature, and humidity. These systems need regular maintenance to ensure that they meet cleanroom specifications.

In conclusion, *cleanroom control* is a complex, ongoing process that integrates various systems and technologies to maintain a contamination-free environment. It ensures that sensitive processes or products are protected from environmental factors such as particulate contamination, humidity fluctuations, and temperature variations. The goal is to provide a safe, controlled space that meets specific industry standards and regulatory requirements.

Cleanroom audit

A cleanroom audit is a systematic evaluation process conducted to ensure that a cleanroom facility is operating according to regulatory standards, industry best practices, and the specific requirements for the products or processes it supports. Cleanroom audits are critical for verifying compliance with standards like *ISO 14644, Good Manufacturing Practices (GMP), and FDA regulations (for pharmaceutical and biotechnology industries). The audit also helps identify potential issues or areas for improvement in the facility’s design, operations, and maintenance.

Key Aspects of a Cleanroom Audit:

Review of Documentation and Procedures:

Standard Operating Procedures (SOPs): Audit teams review the SOPs related to cleanroom operations to ensure they are up to date and compliant with industry standards. These procedures should cover gowning protocols, cleaning routines, personnel access, and emergency procedures.

Maintenance and Calibration Records: Auditors check that all equipment, such as particle counters, HVAC systems, and environmental monitoring systems, are properly maintained and calibrated as per the manufacturer’s recommendations and regulatory requirements.

Training Records: The audit will verify that staff is properly trained on cleanroom protocols and environmental control measures. Training should be documented, and personnel must be aware of the specific contamination control procedures.

Cleanroom Classification:

ISO Classification: A cleanroom audit checks whether the facility meets the required cleanroom classification based on the ISO 14644-1 standard (ISO Class 1 to Class 9). This involves verifying air cleanliness levels, particle count data, and air change rates.

Environmental Monitoring Data: The audit reviews environmental monitoring records (e.g., particle counts, air pressure, temperature, and humidity) to ensure that the cleanroom consistently meets the required environmental conditions.

Airflow and Filtration Systems:

Airflow and Pressure Differentials: Auditors inspect the airflow and pressure differentials between cleanroom areas to ensure that the cleanroom is maintaining proper directional airflow to prevent contamination.

Air Filtration Systems: The audit includes checking the operation and maintenance of HEPA or ULPA filters, which are responsible for maintaining cleanroom air quality. This includes confirming that filter change schedules are followed and filters are operating at the correct efficiency.

Contamination Control:

Microbial Control: The audit checks procedures for controlling microbial contamination, such as routine microbial testing of air and surfaces. These tests help ensure that the cleanroom meets required levels of microbial cleanliness.

Particle Monitoring: Particle counters and contamination monitoring systems are assessed to confirm that they are functioning properly. The audit ensures that particle levels in the cleanroom do not exceed the limits specified for its classification.

#Types of Cleanroom Audits:

1. Internal Audits: Conducted by the facility’s own quality or environmental control team to ensure ongoing compliance and identify any areas needing improvement.

2. External Audits: Performed by third-party auditors, regulatory bodies, or clients to assess compliance with industry standards, regulatory requirements, and best practices.

3. Regulatory Audits: These are formal inspections by regulatory agencies (e.g., FDA, EMA) to ensure compliance with legal and regulatory standards for manufacturing and quality control.

Importance of Cleanroom Audits:

Compliance and Certification: Regular audits help ensure that cleanroom facilities comply with local, national, and international standards. This is essential for maintaining certifications and licenses to operate.

Product Quality and Safety: Cleanroom audits ensure that contamination control systems are functioning correctly, thus preventing product defects or safety issues related to contamination.

Risk Management: Audits help identify and mitigate risks that could affect the quality or safety of products, preventing costly mistakes, recalls, or regulatory violations.

Continuous Improvement: Audits provide valuable insights into areas for process optimization and facility improvements, ensuring the cleanroom operates at peak performance.

Cleanroom equipments

Cleanroom equipment refers to the specialized tools, machinery, and systems used to maintain controlled environmental conditions in cleanrooms. These items are essential for controlling contamination, ensuring the desired levels of cleanliness, and supporting the smooth functioning of operations in environments like pharmaceuticals, electronics manufacturing, biotechnology, and semiconductor fabrication.

Here’s an overview of key cleanroom equipment:

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Purpose: HVAC systems are essential for maintaining the temperature, humidity, and air quality inside cleanrooms. These systems regulate airflow and help maintain the cleanroom’s desired conditions, such as temperature stability (typically between 18°C to 24°C) and humidity control (usually between 30-60%).

Key Features: High-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filters, air handling units (AHUs), and ducting systems designed to provide clean, filtered air.

HEPA/ULPA Filters

Purpose:HEPA (High-Efficiency Particulate Air) filters and ULPA (Ultra-Low Penetration Air) filters are used to remove particles from the air to meet cleanliness standards. These filters are crucial for maintaining the particle count at acceptable levels (ISO Class 1 to 9).

Key Features: HEPA filters capture particles as small as 0.3 microns, while ULPA filters capture even smaller particles, down to 0.12 microns.

Cleanroom Garments

Purpose: To prevent contamination from human particles (skin cells, hair, etc.), personnel entering cleanrooms are required to wear protective clothing.

Key Types:

Gowns: Full-body suits made of non-linting materials.

Gloves: Typically latex or nitrile gloves, designed to prevent hand contamination.

Face Masks/Face Shields: Worn to prevent the release of microorganisms from breathing.

Shoe Covers and Booties: To keep contaminants from shoes out of the cleanroom.

Hair Nets and Hoods: Worn to prevent hair from contaminating the environment.

Air Showers

Purpose: Air showers are used to decontaminate personnel before they enter a cleanroom. They blast high-velocity air to remove particles from clothing and equipment.

Key Features: Air showers are typically placed at entry points to the cleanroom, and personnel must pass through them to remove contaminants that may have adhered to their clothing or equipment.

Cleanroom Pass-Throughs

Purpose: Pass-through chambers are designed to transfer materials between cleanrooms or between clean and non-clean areas without contaminating the cleanroom environment.

Key Features:These chambers often have interlocking doors that prevent both from being opened at the same time, maintaining pressure differentials and preventing contamination.

Cleanroom devices

Cleanroom devices are specialized tools and instruments designed to help maintain the controlled environment of a cleanroom. These devices are essential for controlling contamination, monitoring environmental parameters, and ensuring compliance with industry standards. They assist in maintaining air quality, temperature, humidity, particle counts, and other factors that contribute to the cleanroom’s effectiveness.

Here is a list of cleanroom devices commonly used in cleanroom environments:

Particle Counters

Purpose: These devices are used to measure the concentration and size of airborne particles in cleanrooms. The particle count is used to determine if the cleanroom meets the required cleanliness classification (e.g., ISO 14644-1).

Key Features: They can detect particles as small as 0.3 microns and are often used for real-time monitoring to ensure that particle levels stay within acceptable limits.

Airflow Meters

Purpose: Airflow meters measure the rate at which air is moving in a cleanroom, typically in cubic feet per minute (CFM) or liters per second (L/s). These devices help to monitor air changes per hour (ACH), a critical factor in maintaining cleanroom standards.

Key Features: Many airflow meters are designed to be non-intrusive and are easy to use for spot checks or routine maintenance.

Pressure Differential Monitors

Purpose: These devices measure the pressure difference between the cleanroom and surrounding areas, ensuring that the cleanroom maintains the correct pressure differential to prevent contamination ingress.

Key Features: They are essential in monitoring positive or negative pressure rooms and are often integrated into the building management system (BMS) to send alerts if the pressure falls outside of acceptable ranges.

Temperature and Humidity Sensors

Purpose: Temperature and humidity sensors are used to monitor and control the environmental conditions inside a cleanroom. These sensors help ensure that the cleanroom maintains the appropriate conditions for both personnel and products.

Key Features: They are often linked to automated control systems that adjust the HVAC systems to maintain desired temperature and humidity levels.

HEPA and ULPA Filters

Purpose: High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are used to trap airborne particles. They are essential components of cleanroom air handling systems.

Key Features: HEPA filters capture particles as small as 0.3 microns, while ULPA filters can capture particles as small as 0.12 microns, offering even higher filtration efficiency.

Cleanroom Gloves

Purpose: Cleanroom gloves are worn to prevent contamination from human hands. They are made of materials such as latex, nitrile, or vinyl, designed to minimize shedding of particles.

Key Features: The gloves are often powder-free and have low particulate generation to prevent contamination. They also provide a barrier for handling sensitive materials.